Capabilities

Our CNC O.D. Grinding department is equipped with five late model Studer grinders and a Luren thread grinder for the best precision and surface finishesCutting-edge equipment from Studer, Mazak, Zeiss, and DMG Mori.

Our CNC O.D. Grinding department is equipped with five late model Studer grinders and a Luren thread grinder for the best precision and surface finishesCutting-edge equipment from Studer, Mazak, Zeiss, and DMG Mori.- World-class inspection department (featuring equipment from OGP, Trimos, Tesa, Mitutoyo, Deltronic and Zeiss) provides first-piece approval. Etalon indication micrometers, Mitutoyo drop indictors and Trimos height gauges at a each workstation ensure repeatability.

- Barcode job tracking at each point in the process.

- Shop Floor Control (SFC) system tracks, schedules and reports on the progress of your project.

- Comprehensive engineering and design services, including reverse engineering.

We are capable of producing custom orders to the following specifications:

- Lengths to 39"

- Diameter from .010 to 13”

- Drilling holes as small as .020” in diameter

- Gundrilling waterline holes as deep as 40" within .008 to .010" concentricity, using conventional, plate and counter-rotating gundrilling machines.

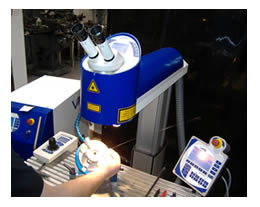

Laser Welding and Component Repair

Hommer Tool is pleased to offer laser welding repair of worn or damaged components, small mold bases and mold plates.

Advantages are:

- Accurate and clean

- No heat exposure or warping

- No sink marks

- Repairs can be done quickly

- Weld sharp corners welding without burning

- More economical than replacing the part

Let us quote your component repair needs!

Equipment Listing

Our modern climate-controlled 24,000 square foot facility houses a vast array of top quality equipment run by skilled machinists.

Our modern climate-controlled 24,000 square foot facility houses a vast array of top quality equipment run by skilled machinists.

- CNC: machining and high-speed hard milling

- CNC: 5th axis high-speed hard milling

- CNC: electrode milling (with robotic capabilities)

- CNC: soft/hard turning

- CNC: form grinding

- CNC 4-axis grinding cam grinding

- CNC ID/OD grinding

- CNC thread grinding

- Centerless grinding

- Gundrilling

- CNC wire EDM

- CNC die-sinking EDM (with robotic capabilities)

- EDM hole drilling

- Honing

- Polishing

- Engraving

- Zeiss scanning CMM

- In-house laser welding for component repair