Engineering

Hommer Tool & Mfg, Inc., we create custom precision components for use in injection molds and die-cast tools. It’s what we do. Our team of expert mold and tooling professionals utilize state-of-the-art technology to meet our clients’ most demanding specifications.

At Hommer Tool, we specialize in crafting precision components for injection molds and die-cast tools. Our skilled team of mold and tooling professionals leverages advanced technology to meet even the tightest tolerances.

With extensive experience in mold making and tooling, we have the knowledge and resources to tackle the toughest manufacturing challenges. By working closely with your engineering team, we ensure a seamless transition from concept to final product—all while meeting your quality, timeline, and cost goals. Collaboration is at the heart of our process. We maintain clear and consistent communication at every stage, acting as an extension of your team to drive success.

Quality Assurance

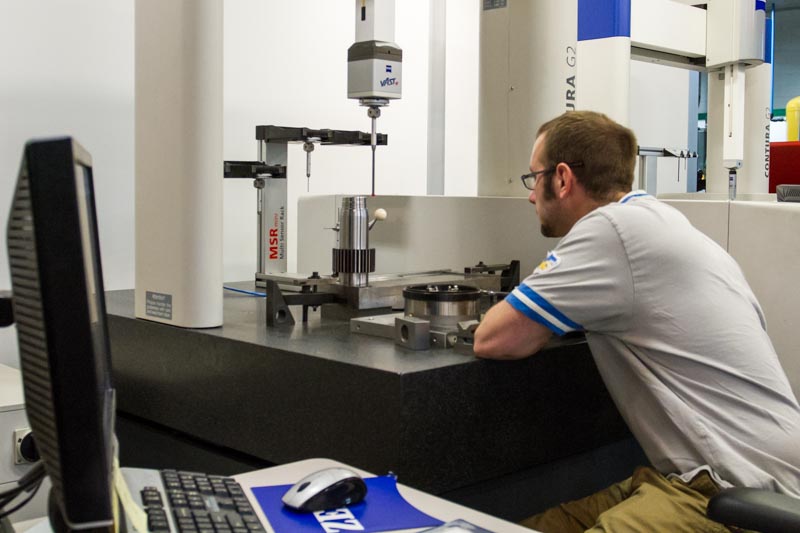

At Hommer Tool, our dedicated Quality Control team ensures precision at every stage of the manufacturing process. Each component undergoes thorough inspection for dimensional accuracy, surface finish, roundness, flatness, and concentricity—guaranteeing reliable, consistent performance throughout the life of your tools.

We utilize advanced equipment and the latest technology to perform first-piece, in-process, and final inspections. Our coordinate measuring machine (CMM) is used to inspect critical features of electrodes, cores, cavities, pins, and other components with high precision. For every completed component, we can provide a comprehensive inspection report upon request.

In addition to our inspection capabilities, we offer direct technical support for all your quality assurance needs. Hommer Tool & Mfg., Inc. is proud to be ISO 9001:2008 certified.

Materials of Construction

- 400 Series Stainless

- Low Carbon Steels

- H-13

- S-7

- A-2

- A-6

- A-10

- D-2

- M-2

- CPM-M4

- CPM-10V

- CPM-15V

- Aluminum – 6000/7000

- Beryllium Free Copper

- Mold-Max HH

- Moldstar

- Uddeholm Products

- Ampco Type Materials

- W360

- M390

- NAK 55

- Many other materials available upon request!

File Formats

Our engineering team is well-equipped to receive your part designs in a multitude of file formats. The following are examples of software we commonly use:

- STEP 203/214 (.stp /.step)

- Parasolid (.x_t)

- IGES (.igs /.iges)

- SolidWorks (.sldprt /.slddrw)

- PDF (.pdf)

- .dwg / .dxf

Among many other formats that we can accept!

Reverse Engineering

If you don’t have prints for your part, our innovative team can transform your sample part into reality. We have the capabilities to create a new print from scratch. Our team will collaborate with you to come to the most effective plan.